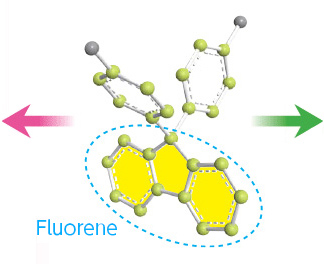

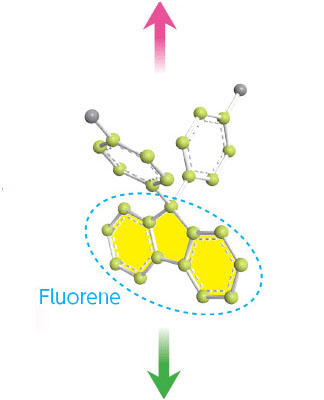

Epoxy: Fluorene based epoxy resin

Therefore, it can be expected superior properties compared to those of conventional epoxy resins.

Features of Fluorene epoxy resins

Solid grade

High heat resistance

High elastic modulus

Low-modulus at high temperature

Low liner expansion

Low water absorption rate

Low dielectric loss tangent

High refractive index

Liqiud grade

High heat resistance

High flexibility

Low water absorption rate

High adhesion strength

High refractive index

Grade Lineup(epoxy resin data)

| Solid grade | Liquid grade | Reference | ||||

|---|---|---|---|---|---|---|

| Product name | OGSOL PG-100 |

OGSOL CG-500 |

OGSOL EG-200 |

OGSOL EG-280 |

Bis-A epoxy | |

| Appearance | - | White solid | Yellow solid | Viscous solid | Light yelow liquid | Clear liquid |

| Epoxy equivalent | g/eq | 260 | 310 | 290 | 460 | 190 |

| Total chlorine | ppm | 1,200 | 1,900 | 490 | 170 | - |

| Viscosity | mPa・s | 350 (150℃) |

3,200 (180℃) |

57 (150℃) |

7,440 (25℃) |

2,350 (25℃) |

| Refractive index (589nm:D line,25℃) | - | 1.64 | 1.70 | 1.62 | 1.55 | 1.58 |

| Heat resistance (5% reduction) Under N2 atmosphere |

℃ | 354 | 400 | 389 | 368 | 380 |

| Compatibility

Mixing ratio:50/50

Judgement criteria: ◎ Re-pecipitation was not confirmed. ○ The tendency to re-precipitation was seen. |

Bis-A epoxy | ◎ | ◎ | ◎ | ◎ | ‐ |

| Bis-F epoxy | ○ | ◎ | ◎ | ◎ | ‐ | |

| Phenol novolak | ○ | ◎ | ◎ | ◎ | ‐ | |

| Features | ‐ |

|

|

|

|

‐ |

Data of materials Cured with phenol

(Curing agent:Phenol nobolak Curing catalyst:TPP Curing Condition:175℃,5 hours)

| Solid grade | Liquid grade | Reference | ||||

|---|---|---|---|---|---|---|

| Product name | OGSOL PG-100 |

OGSOL CG-500 |

OGSOL EG-200 |

OGSOL EG-280 |

Bis-A epoxy | |

| Tg(DMA) [℃] | tanδ JIS K 7244 |

181 | 217 | 132 | 20 | 135 |

| Tg(TMA) [℃] | JIS K 7197 | 166 | 192 | 123 | -4 | 122 |

| Linear expansivility(25℃-150℃) [ppm] |

61 | 66 | 77 | 83 | 89 | |

| Linear expansivility(150℃-240℃) [ppm] |

153 | 126 | - | - | 175 | |

| Flexual modulus(25℃) [Mpa] |

JIS K 7171 | 3,250 | 3,540 | 3,000 | - | 2,910 |

| water absorption rate [%] | JIS K 7209 | 0.18 | 0.15 | 0.20 | - | 0.17 |

| Dielectric constant [εγ] | ASTM D 150 1GHz |

3.3 | 3.3 | 3.3 | 3.9 | 3.3 |

| ASTM D 150 10GHz |

3.0 | 3.0 | 3.0 | 3.3 | 3.0 | |

| Dielectic [tanδ] | ASTM D 150 1GHz |

0.031 | 0.027 | 0.036 | 0.102 | 0.034 |

| ASTM D 150 10GHz |

0.032 | 0.029 | 0.033 | 0.081 | 0.034 | |

| Bond test(copper) [N] | Speed:50mm/min Peeling distance:10mm JIS K 6854 |

0.9 | 1.2 | 1.2 | > 2.0 | 1.1 |

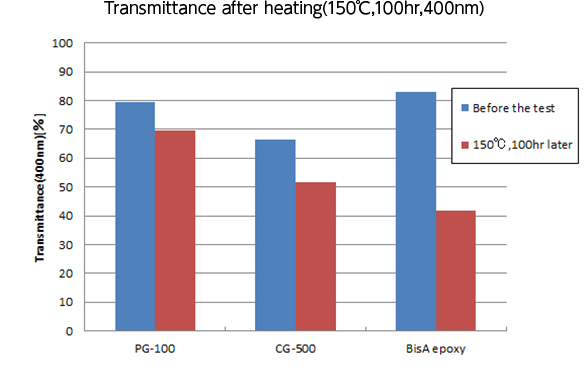

Thermal yellowing test(PG-100,CG-500)

Features of PG-100, CG-500 is that color change when heated at 150℃ less than Bis-A epoxy.

| OGSOL PG-100 |

OGSOL CG-500 |

Bis-A Epoxy Resin (Reference) |

|

| Before the test |  |

|

|

| 150℃ × 100hr later |  |

|

|

- Curing condition:115℃,5hours

- Curing agent:MeHHPA

- Curing catalyst:TPP

- Thickness:200μm

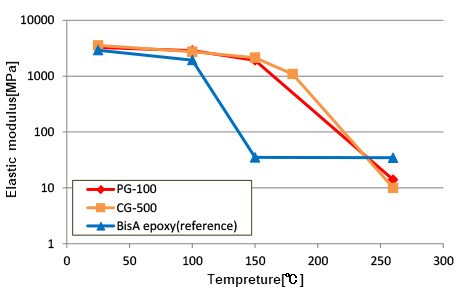

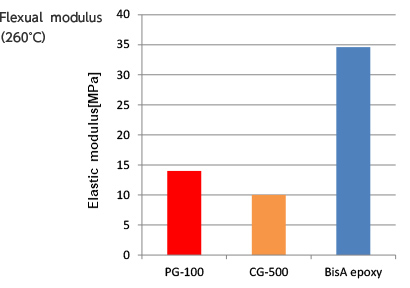

Elastic modulus by each temperature(PG-100,CG-500)

Fluorene epoxy resin has unique properties that keep high elastisity at some temperature,

while dramatically dropped at a high temperature.

- Curing condition:115℃,5hours

- Curing agent:MeHHPA

- Curing catalyst:TPP

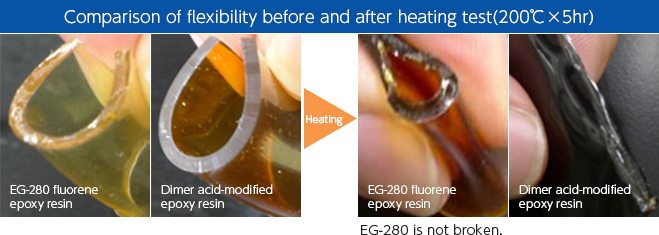

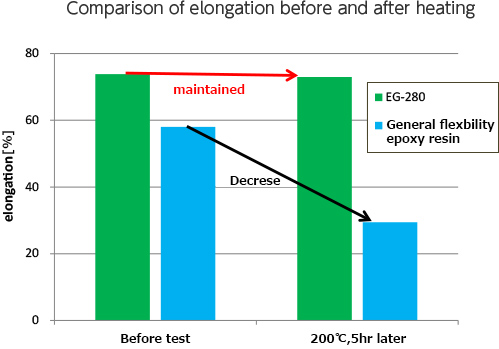

Thermal deterioration test(EG-280)

EG-280 is maintained flexibility compared with general-purpose flexibility epoxy resin.

- Curing condition:115℃×5hours

- Curing agent:Phenol novolak

- Curing catalyst:TPP 1wt%

* Values in the tables are for reference only, not guaranteed for the products.