Polyolefin resin modifier

Features

Polyolefin resin compatible

High adhesion

Improvement in durability

Inhibition of the oxidation degradation

High water repellency

Application Examples

Car parts

Packaging films

Resin pipes

Building materials

Physical Properties Table

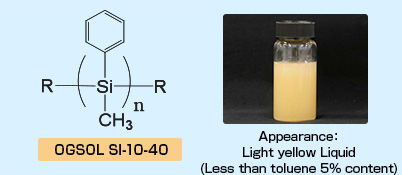

| OGSOL SI-10-40 | ||

|---|---|---|

| Appearance | - | Light yellow Liquid (Less than toluene 5% content) |

| Molecular weight | Mn | 620 |

| Mw | 700 | |

* Masterbatch containing 10wt% SI-10-40 is provided.

Solvent solubility

- Measurement conditon: SI-10-40 is solved in the solvent on the below Table by using a shaker at room temperature.

- Evaluation method: 10wt% solution was obtained at 1 hour ( ○ ) or not( × ).

Ethers

Aromatic series

Ketones

Alcohols

THF

Toluene

acetone

MEK

Ethanol

i-Propanol

OGSOL SI-10-40

○

○

×

○

×

×

| Ethers | Aromatic series | Ketones | Alcohols | |||

|---|---|---|---|---|---|---|

| THF | Toluene | acetone | MEK | Ethanol | i-Propanol | |

| OGSOL SI-10-40 | ○ | ○ | × | ○ | × | × |

Resin properties

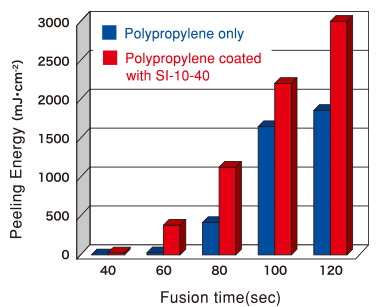

Adhesion data

After Polypropylene films coated with SI-10-40 are pasted each other, the interface between the films is fused rapidly by the heat.

Therefore, it improves the property of the adhesion intensity.

Fusion conditions :160℃, 120sec , 0.05MPa

Testing method :T-peel test

Thickness of Polypropylene films :0.5mm

* Measurement data of Professor Katsuhisa Tokumitsu

(The University of Shiga Prefecture)

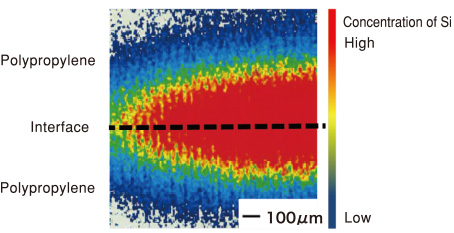

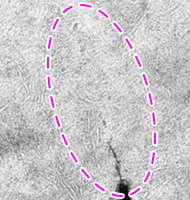

Silicon mapping

SI-10-40 has the high permeability to polypropylene resin.

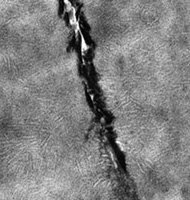

TEM

After the interface between polypropylene films coated with SI-10-40 is fused by the heat, the lamellar structure is observed at the fused interface of the polypropylene films.

with SI-10-40

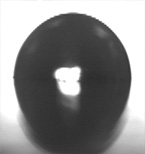

Water repellency

Polyethylene resin(medium density) containing 3wt% SI-10-40 has the superior water repellency.

Polyethylene only

Polyethylene containing

3wt% SI-10-40

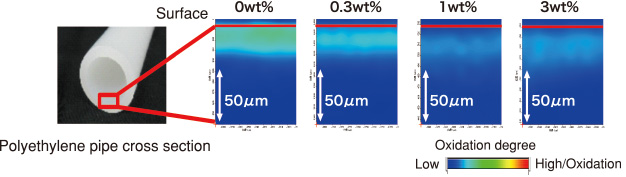

Inhibition of the oxidation degradation / Effect of Copper inhibitor

Polyethylene resin(medium density) containing 3wt% SI-10-40 inhibits the oxidation degradation.

Evaluation method: After immersion in 10 wt% CuCl2aq for 4500 hours, Polypropylene pipe was obserbed by FT-IR images.