Flow improver for engineering plastics OGSOL MF-11

It is highly compatible with both crystalline and non-crystalline resins, and improves fluidity without deteriorating the resins' own properties. Therefore, it is favorable for improving processability of resins.

Features and effects

Since it enables fluidity improvement of resins with maintaining other properties,

MF-11 is favorable for a resin modifier to improve molding processability.

Result of addition to polyamide (PA66) resin

(Non reinforced, GF reinforced, CF reinforced)

Great improvement of MFR

Improvement of elastic modulus

Preserving other properties

Applications for which MF-11 is especially effective

Low temperature molding

Thin-wall molding

Precision molding

Highly-filled molding

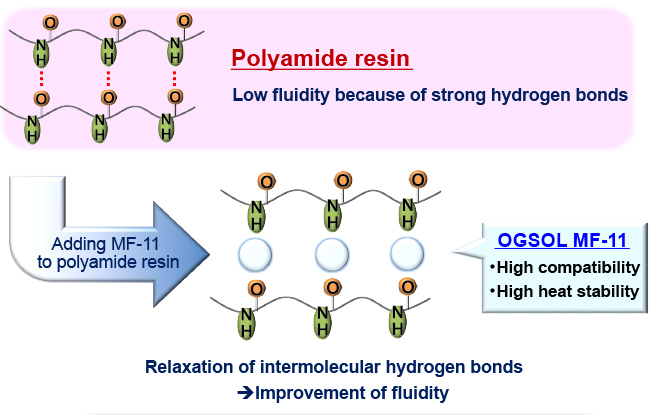

Concept

MF-11 is favorable for improving processability of polyamide resins.

PA66 resin modification data with MF-11

| Measurement item | Ref. | MF-11_5% | MF-11_10% | Measuring conditions |

|

|---|---|---|---|---|---|

| PA66 | wt% | 100 | 95 | 90 | ― |

| MF-11 | wt% | 0 | 5 | 10 | ― |

| MFR | g/10min | 31.6 | 82.7 | 123.4 | ISO 1133 265 ℃ , 2.16 kg |

| Tensile strength | MPa | 90.2 | 94.4 | 91.8 | ISO 527 |

| Tensile elongation | % | 6.0 | 8.7 | 4.0 | |

| Flexural strength | MPa | 126.8 | 131.4 | 136.5 | ISO 178 |

| Flexural modulus | GPa | 3.1 | 3.2 | 3.3 | |

| Impact strength | kg・cm/cm2 | 3.5 | 2.9 | 2.4 | ISO 180 (With notch) |

| Heat deflection temperature |

℃ | 61.4 | 61.4 | 62.0 | ISO 75 1.8 MPa |

| Saturated water absorption ratio |

% | 7.9 | 7.4 | 7.1 | 100 ℃×72 hr Water immersion |

| Melting point | ℃ | 275.3 | 272.2 | 271.5 | DSC 10 ℃/min |

Addition of MF-11 improves fluidity of PA66,with almost maintaining other properties.

PA66/GF resin modification data with MF-11

| Measurement item | Ref. | MF-11_5% | MF-11_10% | Measuring conditions |

|

|---|---|---|---|---|---|

| PA66 | wt% | 50 | 47.5 | 45 | ― |

| MF-11 | wt% | 0 | 2.5 | 5 | ― |

| GF | wt% | 50 | |||

| MFR | g/10min | 3.9 | 11.7 | 22.4 | ISO 1133 280 ℃ , 2.16 kg |

| Tensile strength | MPa | 243.4 | 248.8 | 256.7 | ISO 527 |

| Tensile elongation | % | 4.0 | 4.0 | 2.0 | |

| Flexural strength | MPa | 393.6 | 385.2 | 401.2 | ISO 178 |

| Flexural modulus | GPa | 16.2 | 16.6 | 16.9 | |

| Impact strength | kg・cm/cm2 | 18.0 | 16.7 | 15.6 | ISO 180 (With notch) |

| Heat deflection temperature |

℃ | 243.0 | 241.5 | 234.7 | ISO 75 1.8 MPa |

| Saturated water absorption ratio |

% | 3.8 | 3.5 | 3.4 | 100 ℃×72 hr Water immersion |

| Melting point | ℃ | 270.1 | 269.1 | 267.9 | DSC 10 ℃/min |

Addition of MF-11 improves fluidity of PA66/GF, with almost maintaining other properties.

Capillary rheometer results

Addition of MF-11 reduces melt viscosity of PA66/GF in wide range of shear rate.

Spiral flow results

Addition of MF-11 improves spiral flow length of PA66/GF without depending on molding conditions.