Carbon Molecular Sieves (CMS)

CMS

CMS is the crucial element of any PSA-Plant for the generation of Nitrogen. The PSA process provides an in-house, indepedent Nitrogen supply at low cost for ineritizing storage tanks, piplines and tankers, for processing and storing perishable foods and beverages, for heat treatment of metals, for processing plastic and fibers, in microchip production and many other applications.

PSA process

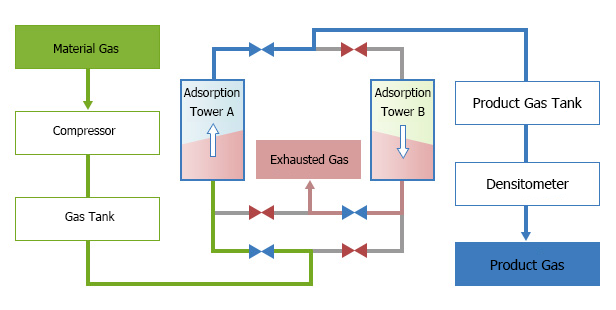

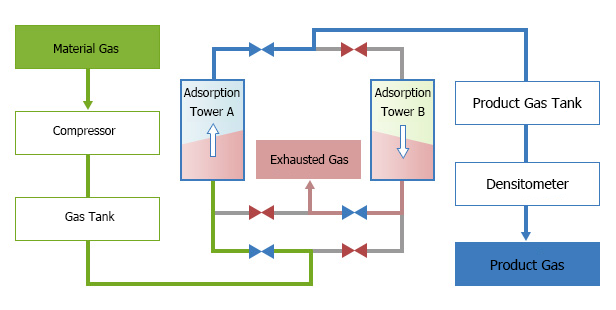

The quantity of gas adsorbed by activated carbon depends on temperature, gas pressure, gas composition, and adsorption velocity. Pressure Swing Adsorption makes use of cyclic pressurization and depressurization steps, where more gas is adsorbed at high pressure and then released when the pressure is reduced. PSA does not require heat energy, and the desorption-adsorption conditions can be adjusted by switching pressurization and depressurization. This enables PSA to operate at a short cycle time. The figure below illustrates a typical PSA system. Pressured raw gas is directed to A, one of two adsorption vessels packed with CMS. Under high pressure, while preferentially adsorbed gas constituents remain in the CMS bed, other constituents pass through the vessel to produce purified product gas. When the vessel A has reached its adsorption capacity, the raw gas is directed to vessel B and vessel A is depressurized. Adsorbed elements are thus released and the CMS is ready for another cycle. The cycling between the two vessels enables the continuous production of purified gas.

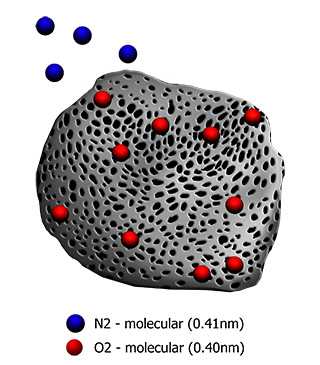

Nitrogen/Oxygen separation

The figure shows the difference in size between O2 and N2 molecules. With their well-defined pore size, Osaka Gas Chemicals high selectivity CMS grades are used as adsorbents for high performance PSA systems.

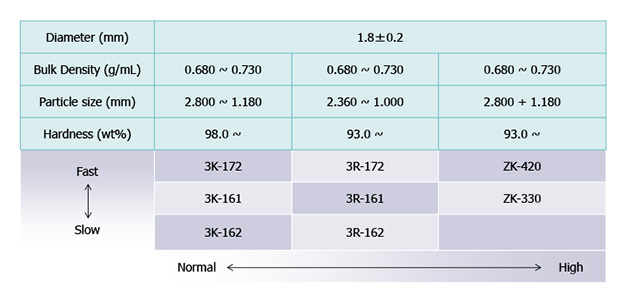

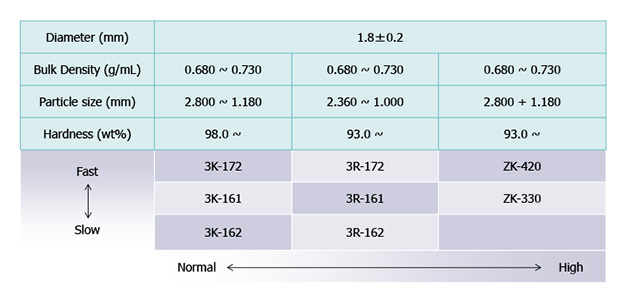

Line of OGC's CMS